Search This Supplers Products:Development and production of asphalt mixing plantResearch and development and production of road and bridge construction maintenance equipmentDevelopment and production of recycling asphalt mixing plantConstruction waste treatment and resource utilization equipment and related spare partsInstallation and debugging of asphalt mixing plantChina LB asphalt mixing plant for road construction DG

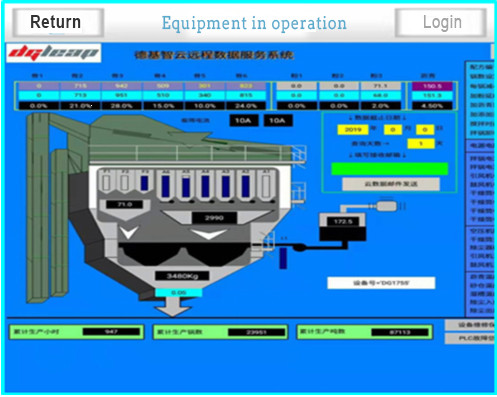

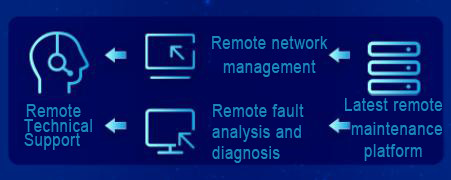

DGLEAP icloud remote control system

time2020/08/12

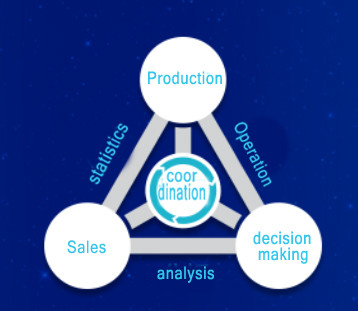

- The epidemic prevention and control blocked the pace of our construction, while possessing an asphalt plant with a "smart brain" allows you to understand the overall data of the device at home. Making good use of D&G latest DGLeap system, let data transmission be accurate, let device management be easy.

In terms of ability

Remote data system:Provide customers with simple and useful data statistics services

In terms of method

1. Remote data service is simple but very practical: it can help customers to understand the details and status of plant operation in real time, realize the storage and backup of production data in the cloud, implement the real-time statistics of production reports on the web page of the computer, and also query according to the year, month, day, hour and minute.

2. It can send the production data to the designated mailbox of the customer, with good confidentiality and data integrity.

4.It can be reviewed by PC and mobile APP.